Improving lithium-ion battery production with targeted digitalisation strategies

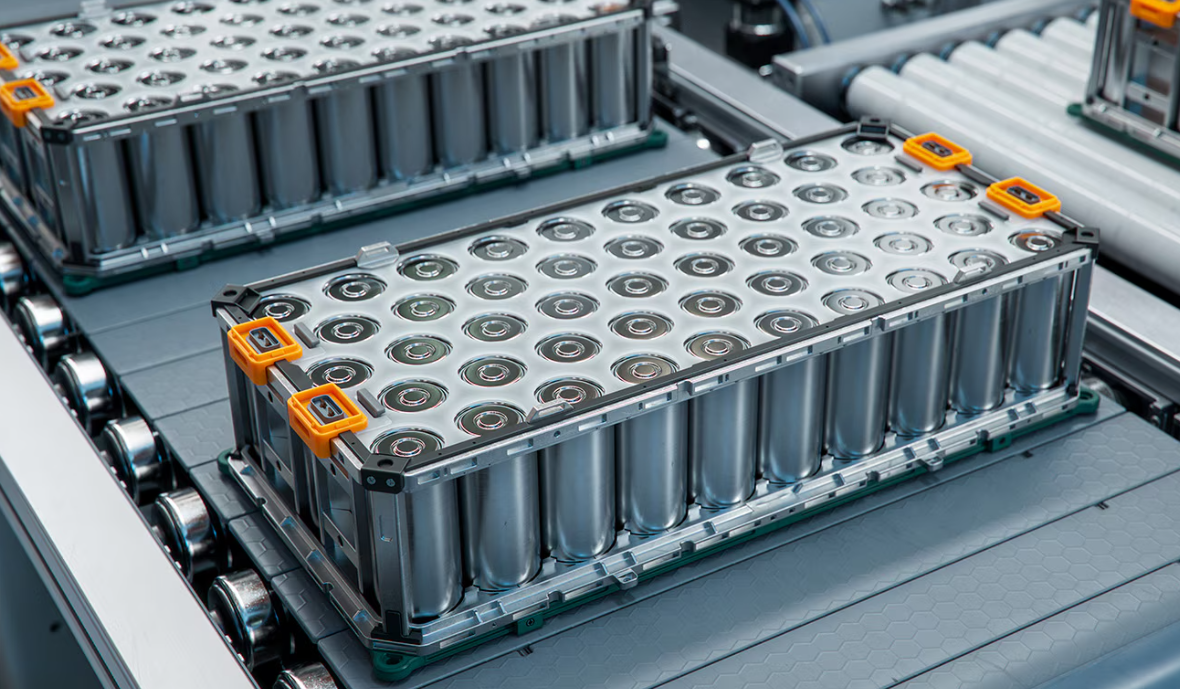

Lithium-ion batteries require expensive raw materials and undergo a particularly complex production process with high scrappage rates. If manufacturers are going to be able to scale up their operations and help EVs take their place at the heart of the transport sector, they need every possible advantage they can find.

One approach that can help deliver this advantage is digitalisation — the implementation of digital technologies to harvest and process the vast quantities of data produced in modern manufacturing, delivering insights to realise tangible benefits to the production process.

Meeting rising demand

It is very hard to overstate just how dramatically the lithium-ion battery sector is set to grow over the coming decade. Rising demand from the EV sector has already helped the global market expand from around US$40 billion in 2018 to more than US$60 billion in 2022, and this growth rate is only projected to accelerate. By the end of the decade, it’s predicted that the market will be worth more than a quarter of a trillion dollars1.

By the end of the decade, it’s predicted that the global lithium-ion battery sector will be worth more than a quarter of a trillion dollars.

Source: Mitsubishi Electric Europe, Germany – Data Source: https://www.statista.com/statistics/1339880/global-battery-market-size-by-technology/

However, the sheer scale of this expansion presents several challenges. Not only is competition set to grow incredibly fiercely, but the raw materials used to create lithium-ion batteries are set to become even more expensive as demand rises. Lithium, cobalt and nickel all need to be mined and processed before being used in manufacturing, and the IEA predicts that the total demand for the minerals required for EV production will increase 30-fold between 2020 and 2040.

If the manufacturing sector is going to meet the increasing demand for EVs, it’s vital that production is made as efficient as possible. However, one of the key challenges currently facing the battery sector is implementing effective quality control and tackling high wastage rates.

Despite being made from valuable materials, a typical plant can expect to see about 10% of finished products fall short of the minimum standards and end up as scrap. In many cases, this rate can climb as high as 30%. This high level of scrappage is incredibly expensive, and is one of the reasons why the battery typically represents up to 60% of the total cost of an EV.

This isn’t due to carelessness or irresponsible behaviour on behalf of manufacturers. Rather, it is because the manufacturing process itself makes it extremely hard to implement traditional quality control measures.

The challenges of lithium-ion battery manufacturing

Lithium-ion battery manufacturing begins with the creation of ribbons (or foils) of metal —copper for the anode and aluminum for the cathode. The size of these ribbons can vary widely, depending on the design and specifications of the batteries being produced, but they are typically several hundred meters long – often stretching over a kilometre at larger manufacturing sites – and anywhere from a few centimeters to over a meter wide.

To turn them into batteries, the ribbons are coated in a thin film of active material slurries. The cathode typically uses materials such as lithium cobalt oxide, lithium iron phosphate, or other lithium metal oxides, while the anode is coated with graphite or silicon-based materials.

Regardless of the materials used, the thickness of these coatings has a major impact on the finished battery’s energy capacity and ion transport efficiency. Thicker coatings can store more active material, potentially increasing the battery’s overall energy storage capacity. However, this benefit comes with a trade-off, as overly thick coatings may impede the movement of lithium ions between the electrodes, reducing the battery’s charging and discharging speeds.

This balance between thickness for increased energy storage and the need for efficient ion transport is critical, as it directly impacts the battery’s performance, especially in EV applications that demand rapid energy delivery. If a coating is too thick or too thin, large sections of a ribbon may not be suitable for use in a finished product.

Though the ideal thickness will vary depending on a manufacturer’s exact requirements, cathode coatings are typically in the range of 100 to 200 μm while anode coatings tend to be slightly thinner, usually around 70 to 120 μm. This is, coincidentally, roughly the range of thickness expected from a human hair.

Unsurprisingly, maintaining a consistent film this thin across an area measuring up to hundreds of square meters is incredibly challenging. Dozens of factors might impact the thickness of the finished product, ranging from the temperature of the film to the humidity inside the plant.

Making sense of this complex, constantly changing data is almost impossible for conventional manufacturing setups. However, this is where the correct implementation of digital manufacturing technologies can help companies excel.