Battery Monitoring

Measurement technology is key to identifying battery problems, and relies partly on having a detailed model of the pack

Battery Monitoring

Monitoring the performance of battery cells in a pack is pushing the limits of technology in many ways. Increasing the accuracy and reliability of the monitoring in the hostile environment of a battery pack, at voltages of more than 800 V and fluctuating temperatures, is a considerable challenge. New ways of getting the data back quickly and reliably to a battery management system (BMS) are being developed, to provide long-term data on them for later use in applications other than vehicles.

Then there are new ways to probe the performance of a battery pack through a digital model. Technology to measure the performance more accurately of all the parts of a pack, including the swelling of cells, can be captured during development and used throughout the pack’s lifetime. That creates new ways to monitor the performance of the pack during operation, giving vehicle developers and operators enhanced visibility of their system designs.

Rechargeable battery packs, particularly ones based on lithium-ion cells, prematurely deteriorate in performance if any of the cells are allowed to over-discharge. As a pack becomes fully discharged, the voltage drop of the weakest cell(s) can overtake the internal chemical potential, and the cell terminal voltage becomes negative with respect to the normal voltage.

In such a condition, irreversible chemical processes begin altering the internal material characteristics that originally provided the cell’s charge storage capability, so subsequent charge cycles of the cell do not retain the original energy content. Once a cell is impaired, it is more likely to suffer from less efficient charging cycles in subsequent use, making the problem worse and shortening the useful cycle life of the pack.

That is critical for the users of EVs of all kinds who want to get the most out of the battery pack, whether it is maximum range or longer operating times.

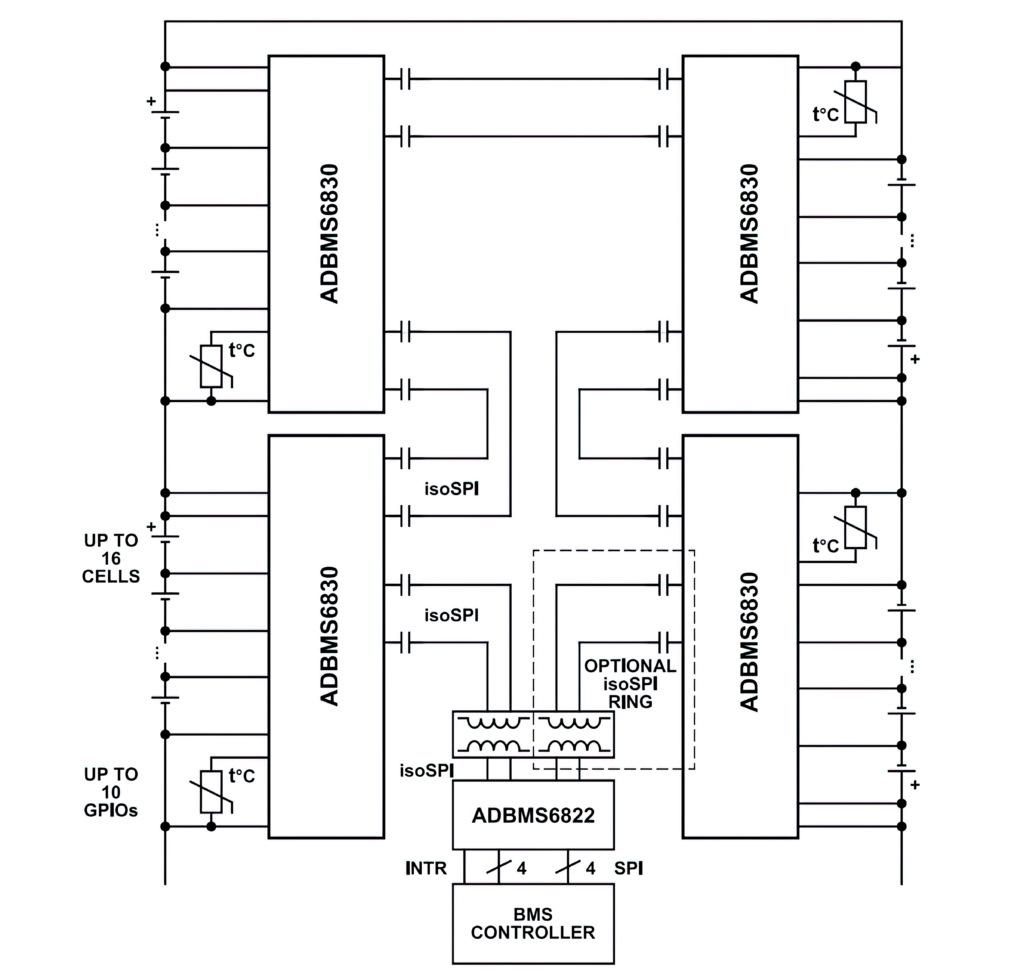

The battery monitoring system is a mix of sensors, voltage measuring chips, comms chips and the BMS itself.

Battery packs can extend up to 800 V and beyond to support the demanding loads of an EV’s motor. This translates into more than 200 lithium-ion cells, each operating at 3.6 V and stacked together in series inside the vehicle. Small variations in the construction of each cell can lead to different performances, with higher or lower current drain than expected. All this needs to be monitored to within a few millivolts, floating at 800 V.

If a cell drains too fast the internal structure can heat up and be damaged. Modern lithium-ion batteries with liquid electrolyte have an optimum operating temperature between 15 and 35 C, but are capable of working outside that range. Next generation solid-state batteries work at high temperatures, currently around 70 C.

While the impact of this damage might not show up immediately, it can lead to higher discharge rates, higher temperatures and the cell swelling up. In the worst case, it can lead to the cell splitting, letting in oxygen and the cell catching fire. Once that happens with one cell, it can quickly spread to the rest of the battery module, the pack and even the entire vehicle.

(Courtesy of Analog Devices)